Scania’s new biogas engines are now paired with two-thirds of the successful Super-based powertrain. The harmonised trio – the new biogas engines plus the G25 gearboxes and axles from the diesel sibling – have achieved fuel savings of 5% in long-haul use.

‘When we paired these components, it soon became obvious that we had a hit in the making,’ says Ola Henriksson, Senior Product Manager for Renewable Fuels at Scania Trucks. ‘Just as the Super engine benefits from the increased spread in the G25 gearbox, so do the biogas engines. When paired with the Scania Opticruise gearbox and the new axles, the biogas engines can usually operate very close to their ‘sweet spot’. Put together, it results in 5% fuel savings from this powertrain.’

The interest in locally produced biomethane fuels for trucks (such as Bio-LNG or Bio-CNG) is rapidly increasing. Many companies and transport buyers plan to decarbonise their road transport here and now. Biomethane-based solutions are readily available via rapidly growing fuel-station networks, and Scania can reduce CO2 emissions by up to 90% from a well-to-wheel perspective.

‘Biomethane fuels are the solution for those customers who want to start a decarbonisation journey without delay,’ says Henriksson. ‘Our biogas engines cover a wide span of industries and applications. A 40-tonne tractor-and-trailer combination can achieve ranges of up to 1,400 km when specified with our biggest Bio-LNG tank solutions. Add the 460 hp and the 2,300 Nm our OC13 engine offers to the equation, and you have a perfect tool for European long-haul.’

Pairing Scania’s new biogas engines with the gearbox (G25) and the rear axle from the Super-based powertrain proved successful. Fuel savings of 5% are confirmed, and with Bio-LNG or Bio-CNG, there will be a CO2 reduction of up to 90%, achievable here and now.

Networks of biogas filling stations are expanding rapidly across Europe, driven by increased demand and by significant players in the fuel industry. Reducing the CO2 footprint is no longer something only ‘green’ companies are doing to win public acclaim; it is necessary for most serious transporters, and we must use all available means.

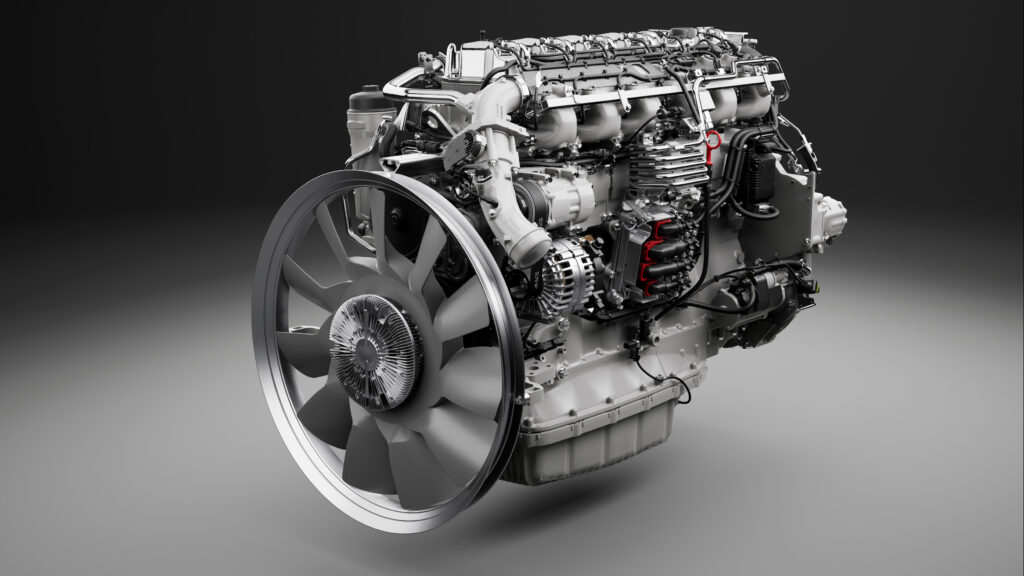

The new biogas engines are based on the 13-litre gas engine that Scania has offered for several years. By increasing their engine power levels and preparing them for future legal demands, Scania is demonstrating its intention to gain an even more significant market share in the quest for decarbonisation.

‘With the CO2 reductions, the driveability and the ranges we offer now, I am convinced that more customers will recognise what a great solution this is,’ says Henriksson. ‘There are so many obvious pros and virtually no cons at all. And the driver can also enjoy a significantly lower noise level.’

Engine data for Scania’s two new biogas engines:

| OC13 103420 hp | OC13 104 460 hp | |

| Type | Inline | |

| Displacement | 12.7 litres | |

| Firing order | 1-5-3-6-2-4 | |

| Cylinders | 6 | |

| Valves per cylinder | 4 | |

| Bore x stroke | 130 x 160 mm | |

| Compression | 12.6:1 | |

| Fuel injection | Bosch + CEM1 | |

| Oil capacity | 43 litre | |

| Emission control | Scania EGR and three-way catalytic converter | |

| Max. output | 420 (311 kW) @ 1900 /min | 460 (340 kW) @ 1900 r/min |

| Max. torque | 2100 Nm @ 1000-1300 r/min | 2300 Nm @ 1000-1300 r/min |